The Motera Cricket Stadium in Ahmedabad, India, has opened its doors following three years in construction where it will serve as the world’s largest cricket venue with a capacity for over 110,000 fans.

Surpassing preceding record holder, Melbourne Cricket Ground’s 100,000 seats, the stadium is double the capacity of the old Motera Stadium and built on the same 63-acre site. It took two years alone to demolish the old venue and construction then took a further three years.

An inauguration event attended by US President Donald Trump and Prime Minister of India, Narendra Modi, saw a full house of visitors to experience the new stadium.

It will be the new home of the Gujarat Cricket Association includes 76 corporate boxes, four team dressing rooms and facilities, state-of-the-art club facilities with three practice grounds, an indoor cricket academy, and a 55-room clubhouse which will have an Olympic-size swimming pool.

Designed by architects Populous, the 360-degree stadium has been deliberately made to be round and open to provide uninterrupted sightlines onto the pitch. The bowl design consists of two large seating tiers, each with approximately 50,000 general admission seats.

Motera Cricket Stadium’s pedestrian flow is also innovative with all vehicular movement on the ground level while pedestrian movement will be on a level above, ensuring clear segregation to limit congestion. General spectators approach from the North side of the stadium, entering on the first floor via a 12m high ramp, which creates a fantastic plaza for fans.

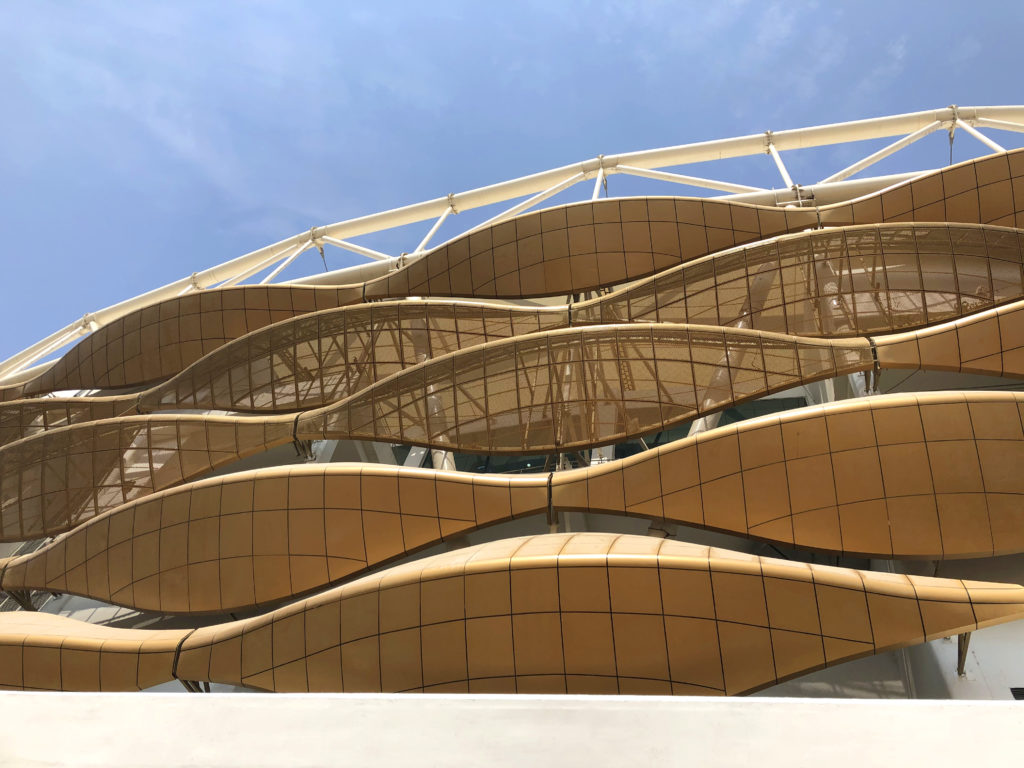

Walter P Moore served as the structural engineer for Motera’s roof system. Taking into consideration the fact that the city of Ahmedabad is located in a level 3 seismic zone, the roof needed to be lightweight to reduce seismic demand and develop an economical roof system. Walter P Moore proposed a tensile fabric roof system that is seismically separate from the concrete seating bowl and supported by steel “V” shaped columns. These columns resist gravity and lateral loads resulting from high winds and earthquakes.

PTFE (polytetrafluoroethylene), Teflon-coated woven fiberglass, was stretched between a circumferential inner tension ring and an outer compression ring. A wind tunnel test was also performed to optimize roof design. Walter P Moore used Load Response Correlation Method to develop critical wind load patterns from the wind tunnel test. The stadium exists in tiers to accommodate smaller events and maintain the atmosphere for spectators even when the bowl isn’t full. These tiers carry through to the roof, making the fact that it is structurally independent a crucial design element.

“Through Walter P Moore, I have worked on a number of sports projects. I grew up in the City of Ahmedabad before moving to the United States over 35 years ago. Designing the roof for the world-class Motera Cricket Stadium was very special for me,” said Viral Patel, principal-in-charge.